Lean Manufacturing Principles Pdf

The five principles are considered a recipe for improving workplace efficiency and include. This research aims at implementing lean manufacturing principles in different industries and re-design the manufacturing system based on the concepts of lean manufacturing by developing a pull.

For Dummies Lean Manufacturing Lean Six Sigma Cheating

The Lean Manufacturing Methodology Lean is a systematic method to reduce waste of all forms in an assembly line in a practical reliable and cost-effective way.

Lean manufacturing principles pdf. Time as the benefit or weight of processes that provide both value and waste from the time of order to the time of shipping. If the following benefits sound like something youd like for your business you need to use lean manufacturing principles. The five-step thought process for guiding the implementation of lean techniques is easy to remember but not always easy to achieve.

The critical insight is. Commercial and Naval Ship Construction Deliverable 22 Submitted by National Steel Shipbuilding Co. Lean manufacturing principles that should help you evaluate lean manufacturing solutions for your own applications.

Improved efficiency effectiveness and even profitability are all byproducts of lean manufacturing. The cost to produce the products and services is then determined. In the book the authors examined the manufacturing activities exemplified by the Toyota Production System.

181 Introduction to Lean Manufacturing Lean manufacturing or lean production are reasonably new terms that can be traced to Jim Womack Daniel Jones and Daniel Roos book The Machine that changed the world 1991. Continuous Flow Lean MachinesSim-plicity Workplace Organization Parts Presentation Reconfigurability Product Quality Maintainability Ease of Access and Ergonomics. Establishing worth allows organizations to create a top to the bottom target price.

Intimidating information most Lean Six Sigma resources provide the methodology is quite understandable. It identifies waste as anything that adds cost to the. 2005 Massachusetts Inst tute of Techno ogy Page Origin and evolution of lean concepts Core lean principles practices How lean differs from craft and mass production models of industrial organization.

Lean Manufacturing Principles Guide Version 05 June 26 2000 Maritech ASE Project 10 Technology Investment Agreement TIA 20000214 Develop and Implement a World Class Manufacturing Model for US. 5 Principles of Lean LEAN thinking is the belief that there is a simpler better easier way to complete our work. Lean manufacturing has enabled businesses to increase production reduce costs improve quality and increase profits by following five key principles.

Make the value-creating steps occur in tight sequence so the product will flow smoothly toward the customer. Typically a valueadded activity must meet three criteria. JIT uses continuous flow and takt time to connect production directly with the pace of the customer sales.

Lean is a New Approach to. Another key lean manufacturing principle is Quality Built In or Jidoka. Further lean manufacturing is an adaptation of the Toyota Production System TPS and its 4 principles.

In the 1950s Taiichi Ohno developer of the Toyota just-in-time Production System created the modern intellectual and cultural framework for Lean Manufacturing and waste elimination. Cost Time Cost not at the expense of people specifically. 80 waste reduction 50 lower production costs 80-90 reduction in standing inventory 90 lower cost of quality its 90 cheaper to make quality products 50 increased labor productivity Lean is a system method school of thought.

Methodology A literature review was used to review the principles of lean manufacturing. Specify value from the standpoint of the end customer by product family. Manufacturing process as traditional assembly lines are usu-ally specialized to produce one specific product.

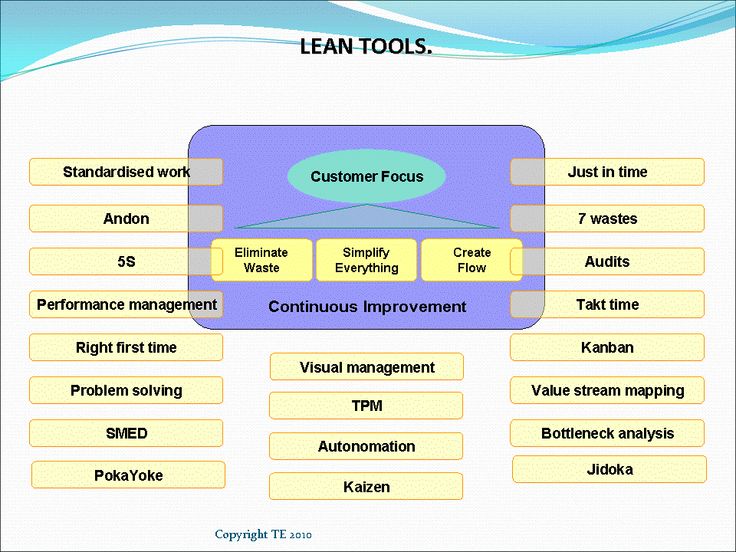

An implementation plan was developed to implement lean manufacturing principles within the assembly through close-up area. The 9 principles discussed are. At its core lean manufacturing is waste elimination and continuous improvement.

Womack and Jones defined the five principles of Lean manufacturing in their book The Machine That Changed the World. Lean Six Sigma is based on clear principles and can be implemented on any process within any industry in manufacturing and service and in companies small to large. 1 defining value 2 mapping the value stream 3 creating flow 4 using a pull system and 5 pursuing perfection.

The idea behind this principle is that quality is built into the manufacturing process. This determines what the customer will pay. This study is specific to Company X.

What is Lean Manufacturing. Identify all the steps in the value stream for each product family eliminating whenever possible those steps that do not create value. Lean Foundry Increasing profitability increasing price or reducing costs.

1 Voice of the Customer Identify who your customer is and identify value from their perspective. Quality Built In Jidoka. On behalf of the Project Team Members.

The study is intended to show the results of implementing lean manufacturing principles. New goals in manufacturing systems --combined benefits of craft and mass production Improved quality. What is your Manufacturing Lead Time from order to shipping.

The fabrication de velopment by mea ns of a succession of business re views 2 5-6. In order to gain a competitive edge many companies have adopted lean manufacturing or lean thinking as a keystone for success in todays global market. Lean manufacturing is a series of applied processes and tools that eliminate waste from production.

Lean Manufacturing is a commerce proposal to reduce waste in manufactured goods. The JIT lean principle along with Jidoka Quality built in are the two pillars of the Lean manufacturing house. Identify value map the value stream create flow establish pull and seek perfection.

In its most basic form Lean Manufacturing is the systematic elimination of waste by focusing on production costs product quality and delivery and worker involvement. The Lean approach begins with a detailed understanding of the value assigned to products or services by the customer.

Pdf Download Going Lean How The Best Companies Apply Lean Manufacturing Principles To Shatter Uncertainty Drive I Lean Manufacturing Good Company Manufacturing

Adapting Lean Manufacturing Principles To The Textile Industry In 2020 Lean Manufacturing Visual Management Textile Industry

The 12 Principles Of Manufacturing Excellence Pdf Thing 1 Thing 2 Excellence Principles

How To Become A Lean Manufacturing Consultant Lean Manufacturing Visual Management Lean Sigma